Keeping our high production standards allows for consistently low reject rates, ensuring our products work perfectly every time.

Reject Ratio of Body Camera

DPPM

Reject Ratio of Docking Station

Pe utilizes a standardized technical review process to ensure the required technology, production quality, and marketability of project requests.

Initial checks are completed for the product plan and project tasks, including preliminary analysis, material and technology requirements, and estimated costs.

Status of proposed design is verified on this stage, along with guiding the development and simplification of the ongoing project plan

Review the design and software of the prototype base, conduct testing and evaluation of the prototype with documented findings.

Check the status of design development makes sure that required changes are implemented; issues are communicated and verified to proper departments.

Verification of applied changes on the hardware and software, along with evaluation of test results before moving to full-swing production.

A comprehensive technical review on manufacturing to meet the requirements for mass production and delivery.

Thanks to over a decade of manufacturing high-class body worn cameras, we have developed an effective supplier management process based on long-time relationships with qualified suppliers.

Suppliers are selected based on several rubrics, including material quality, pricing, and delivery timeframe. The supplier database is annually reviewed to maintain production quality.

We take numerous product tests to ensure our body worn cameras are up to par with the highest market standards.

Multiple stages of testing are done throughout the manufacturing process in order to maintain the quality of our products.

Incoming materials and designs for the project plan are evaluated based on established requirements.

Video, audio, and photo capture, along with other basic functionalities, are tested according to industry standards.

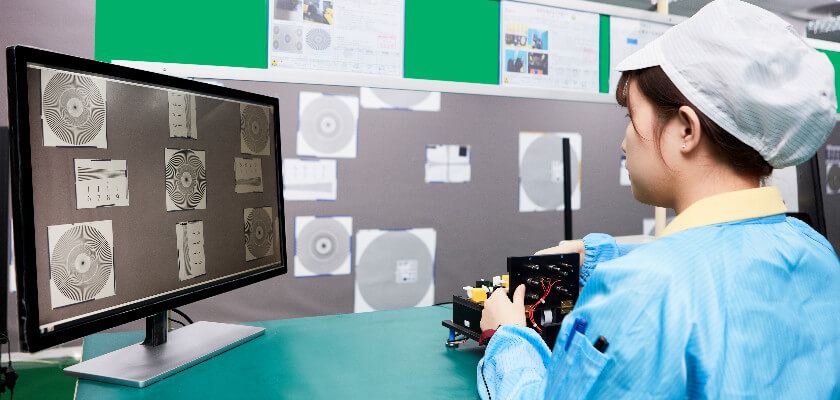

Cameras are checked to ensure the spatial frequency response match across multiple depths in a single image.

Product capabilities, including hardware and software, undergo testing to evaluate overall competency.

Hardware design and assembly is inspected through various tests for durability and aesthetic cohesion.

Product undergoes machine testing and aging testing to guarantee optimal functionality despite extensive use.

A final completed inspection and review is done after packaging, ensuring product and accessories are properly packed.

We partner with over 40,000 law enforcement agencies, with 3,000,000 body cameras deployed in the field.